About Risography

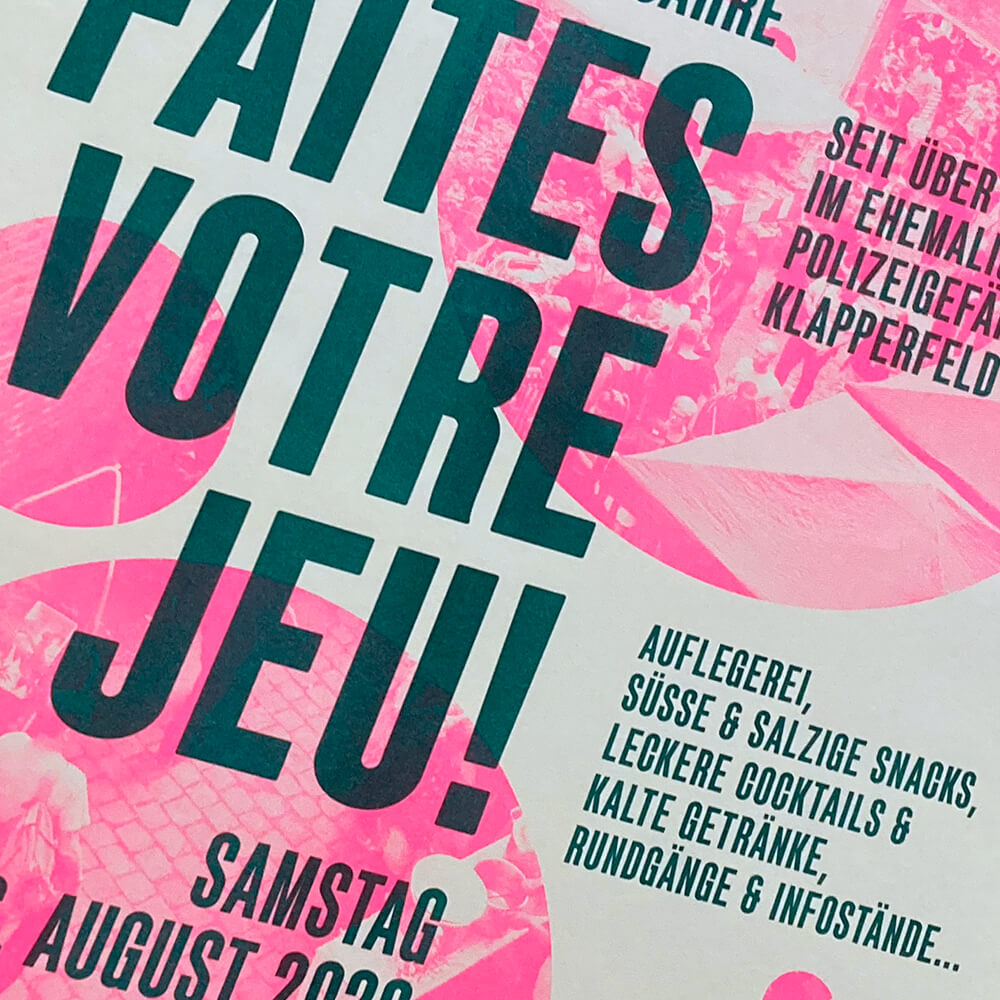

Risograph prints look damn good and the printing process is also one of the most environmentally friendly. The bright colors are based on soybean oil, no toxic chemicals are used. The master copies are made from quickly regrowing hemp fibers. In comparison to laser printing and other types of digital printing, only a fraction of the energy is required since the colours are applied to the paper without heat. In addition, especially in larger print runs, it is very affordable.

Digital

Screen Printing

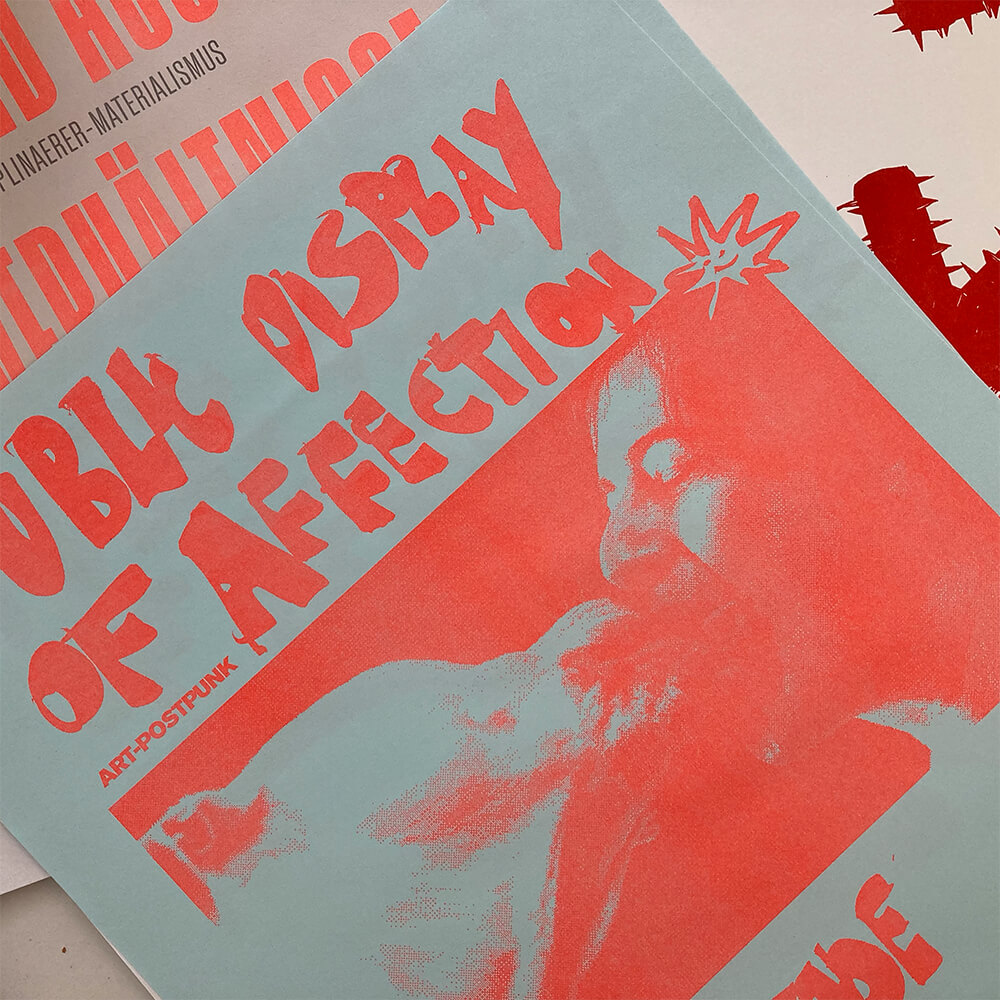

Risography is a stencil or through-printing process. First, a master foil is lasered at all points where ink is to be applied to the paper during printing. The master is then fastened onto a drum with a very fine screen. During the actual printing process, the printing substrate is then moved past the rotating drum and the colour is applied to the paper. That is why Risography is also referred to as digital screen printing.

In 1986, the Japanese company RISO brought the first Risograph onto the market - originally as a cheap mass duplicator for schools and public authorities.

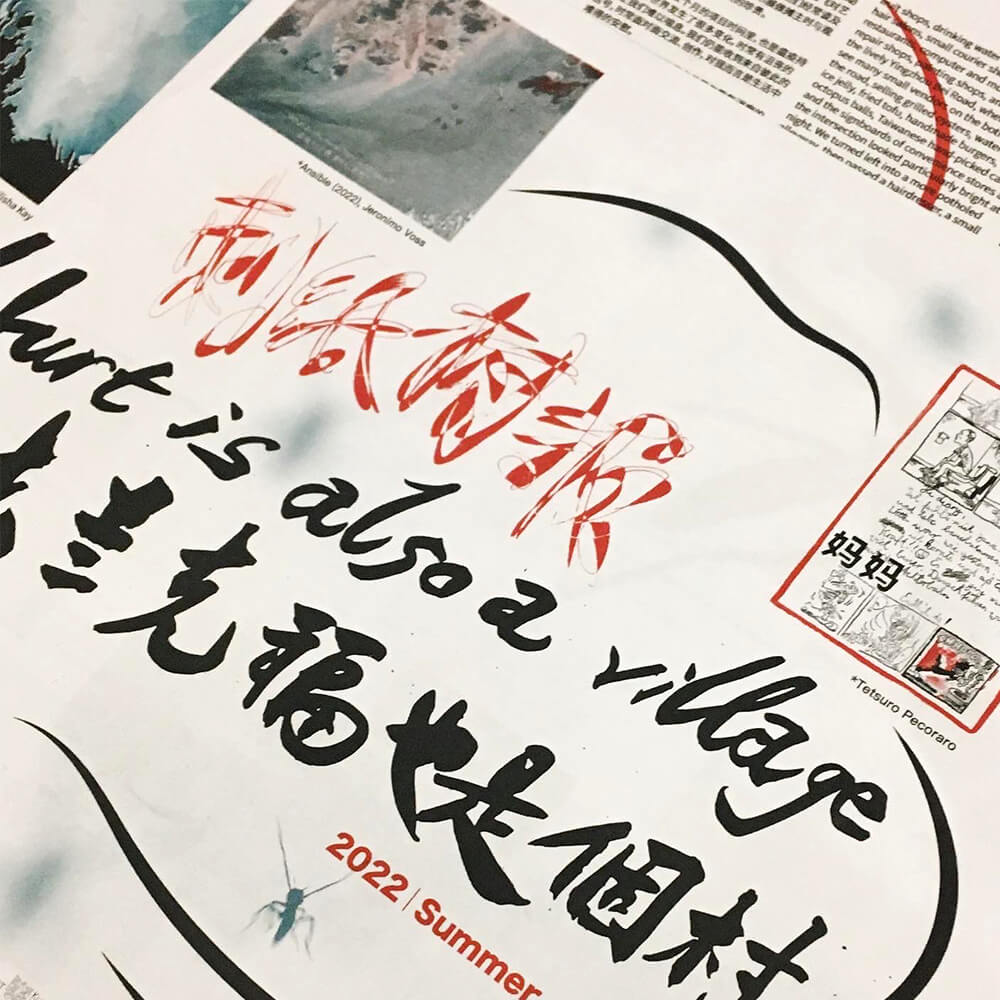

The low production costs and the luminosity and depth of the colors make it very popular with designers, artists, illustrators and small publishers.

Risography differs from other digital printing processes not only in terms of colors, production costs and energy consumption: Each print produced by the Risograph is unique - the ink application varies from sheet to sheet and an offset of a few millimetres when using several colors adds to the special aesthetics of the prints.